Audiences are continually mesmerized by the futuristic technology found in movies. The gizmos rattling about those high-adrenaline moments of intense visual effects enthrall the audience, gluing them to their seats. How close is current technology to the gadgets found in our society’s sci-fi fantasies, though?

The chemical engineers at Tech who participate in the national Chem-E-Car competitions would argue that we are closer than ever before.

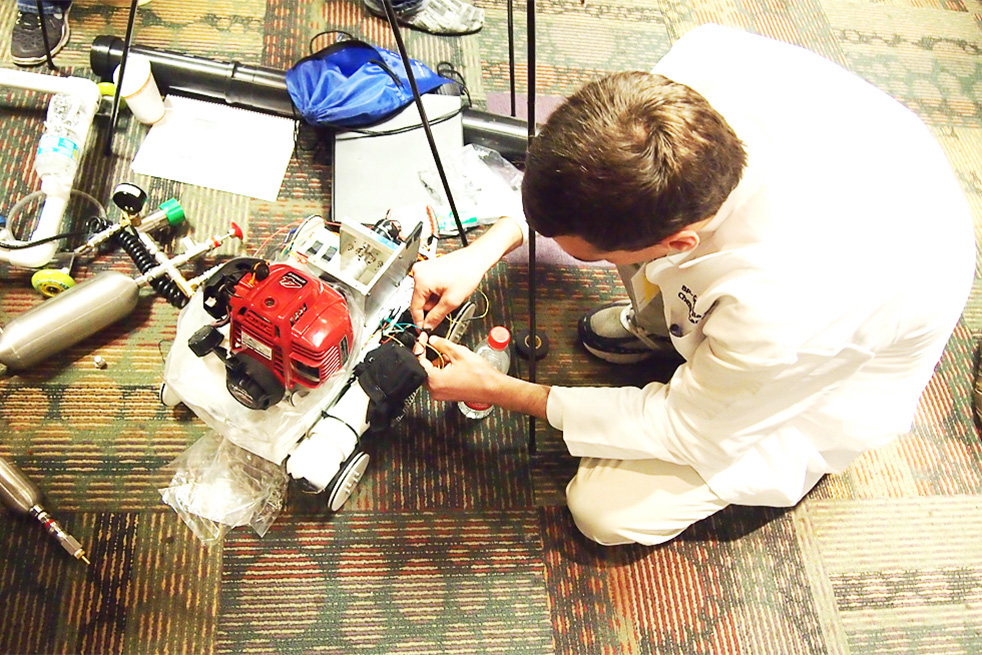

These are not an average car. In addition to their innovative power source, the cars are “shoe box sized” and most not cost more than $2000.

Each year, universities from across the U.S. and the world participate in the Chem-E-Car competition, an event in which students design and construct a car powered by chemical energy and that will safely carry a specified load over a given distance and stop.

The competition spans months, with multiple regional qualifiers conducted in several locations followed by the best of the teams competing ferociously for the championship at the national level.

There, the craziest and most innovative of ideas fuse together to shape a prototype that uses some of the most common resources available and offers a potentially 100 percent clean solution to environmental pollution.

This year, Tech’s team whizzed out the “Ramblin’ Wreck”—a Chem-E-Car which could be the answer to the almost all problems posed by electric and fuel-driven cars today.

After having secured the first two positions at the regional qualifiers, the “Ramblin’ Wreck” made its way to the national finals of the Chem-E-Car competition which was held from Nov. 1 to Nov. 3 in San Francisco, Cali.

Tech’s version of the Chem-E-Car threads together innovation and controlled reaction, which very much sums up the motto of the competition.

Amidst 31 teams across the U.S. and all over the globe, the Ramblin’ Wreck competed fiercely and bagged the fifth-place prize.

The University of Tulsa was the 2013 national winner. Their award was $2000, which was funded by Chevron.

The Chem-E team is an eclectic mix of seven students—Keller Smith, Yu “Leon” Liu, Will Gleason, Phillip Kisembo, Juan Cobian, Nikhil Deshpande and Kamakshi Malhotra, all of whom are multi-talented individuals with interests in activities as diverse as music, dance and extreme adventure sports.

The team has Dr. Clifford Henderson as their long-standing and all-encompassing mentor. The Chem-E club at Tech was founded about five years ago under the mentorship of Dr. Clifford Henderson, from the Department of Chemical and Biomolecular Engineering.

“Dr. Henderson is by far the coolest mentor apart from being a taskmaster,” said Leon Liu, one of the co-captains and a second-year ChBE major.

To the students, he is a “beacon of support” and their success is credited to his ability of picking the best of their ideas and refining them to bridge the gap between conception and successful implementation.

The club and its efforts are funded by BP.

The club conducts meetings every Wednesday. Their operation base is the Unit Operations Lab in the basement of the Ford Environmental Science and Technology building, where they spend hours on Sunday afternoons, giving shape to figments of their imagination.

The idea for the photochromic car arose in the last spring semester and has stood the test of multiple phases before it culminated into a brand new product driven by ultraviolet light.

Given the current market trends, many people wonder whether electric cars are a better alternative to fuel driven cars. Electric cars are “clean,” in the sense that they don’t burn gas, so they are considered to be zero-emission vehicles.

They run on electricity generated from a host of natural resources, which is precisely the focus of the Tech team. They use the most common of resources to build a working vehicle.

The team’s “Ramblin’ Wreck” is powered by a lead-acid battery which is used to drive a motor.

It is stopped by interrupting power to the drive motor which is triggered by a photochromic reaction induced by exposure of a photoreactive film to ultraviolet light.

This is environmentally sustainable because the darkening of the photochromic lens is completely reversible. This means that no new chemicals are required for each run.

The Chem-E-car team will continue to design and construct new innovative and resource friendly and hopefully prize winning cars.